Window Motor

After the car was repainted, I noticed that the driver's window would squeal when it was lowered on a hot day. I determined that the noise was coming from the motor, which I dreaded. When I put the car together 30+ years ago, I really fought to get the wire in and tight so the window would work right.

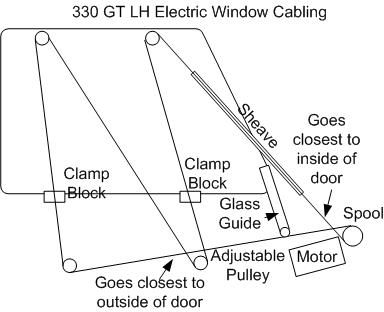

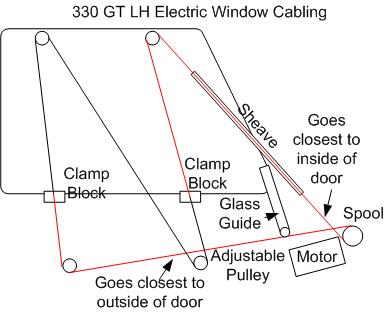

The first thing was to take some pictures of the wire and the routing.

I also made a drawing, noting which wire was in front or back where they crossed.

There is an adjustable pulley that you can raise to give some slack in the wiring. Then you can remove a wire from one of the pulleys so the there is enough slack to remove the motor. Note, the ends of the cable are attached into the spool, with solder balls on them. So there is no removing of the wire before removing the motor.

As you can see, the motor turns the spool in either direction, depending on if the window is being raised or lowered. The window is clamped to the wire by blocks attached to the frame at the bottom of the window.

Once the motor was out, but still attached by the wire, you can remove the spool and wire by tapping the shaft out from the emergency window crank side of the mechanism. Now I had the motor off the car where I could take it to the bench and work on it. Since the squeal only occurred on a hot day (and it was cool), I couldn't make the noise occur when running the motor either way. I decided to go ahead and take apart the motor. When I had the motor alone so I could spin it by hand, there was a noise in one direction, but not the other. So I was pretty sure that the problem was simply needing some grease in the bushings. The motor had never been taken apart based on the original paint on the nuts and I could see no sign of any grease still left after ~50 years. So with some white lithium grease in each bearing and after fiddling getting the brushes back in place, the motor was back together. Here you can see the grease on the worm drive and gear.

Now the fun began. It is difficult to get the wire correctly wrapped on the spool, get the frame holding the spool axle installed and the motor in the car without the wire unwinding on the spool.

My first (of many) passes was to tape the wire on the spool with duct tape. A short piece wouldn't hold, so I wrapped the whole circumference. That held until trying to fit the motor back in the door. This is close to a Chinese puzzle. First the top of the frame has to go in and up. Then the bottom and motor can be squiggled in and the studs put through the inner door metal to attach everything. On the next two passes cable came loose under the duct tape. Finally I got the duct tape to hold by splitting it around where the wires exited the spool. So I got everything in place with the wires on the spools and the window blocks tightened down. I tried to remove the duct tape and couldn't, too good of job. So I used the emergency window crank, figuring that I could pull it off the spool as it rotated using the crank.

All that did was wrap in incoming wire over the top of the duct tape, making it sure that it couldn't be removed. So back to the drawing board. Next I tried to tension both cables so they would stay wrapped as I fiddled the motor in place. I gave up on that after a couple tries. Note, each time the wire gets loose, you have to remove the motor and if you are lucky, untangle the mess and re-wrap the spool. Usually, you have to remove the spool axle frame and rewind everything. The next idea was to clamp the wires onto the shield with Vise Grip pliers.

That seemed to work as the wire stayed tight as I installed the motor. Then I clamped the window so it couldn't drop and loosened the clamps holding the wire to the window frame. By pulling both wires through the blocks as I released the pliers, the wire stayed spooled until I re-clamped the wire to the window. In looking at the drawing below, the red wire in now under tension. It was dicey keeping the both wires tensioned as I released the pliers, loosened the clamp blocks, pulled the extra wire through the block and got the blocks re-tightened.

I finally thought I was making progress. Now I was able to fit the wire around the adjustable pulley and get the whole wire assembly tensioned. Then I tried to move the window up and down using the emergency crank handle. When I got to the bottom, the wire came off the lower left pulley and of course, unwound on the spool. The next couple of tries just got worse. One time, the wire came off the upper right pulley, but hung up on the bolt holding the pulley in place, so it seemed like it was OK until you cranked the window and noticed the problem. Another time, the wire came off the lower left pulley, but jammed between the pulley and its frame, so it looked OK. A couple of times, the pliers didn't hold onto both wires, so I ended up using a pair of Vise Grips per wire. That also let me clamp each wire at a straighter location, so there was less slack to remove when the wire was released. It also meant that I only had to keep the tension on one wire at a time as I released each of the pliers.

Luckily, there is enough room inside the door and enough space to fit the motor, frame and pliers in. Finally, I managed to get everything together, tensioned and the window went up and down with the emergency crank. I had to adjust the height on the wire so the window would go up and down without getting to one end on the spool. In addition, you have to adjust the left and right side to the window ends up even at the top of the window frame. Then I reconnected the wiring and tested using the motor. It all worked and no squeal.

In all, this took about seven hours, one hour to get it apart and six hours to get it back together in one piece and working.

PS, the next day, I drove the car to the local cars and coffee and the inner door handle wasn't working right. It was difficult to open and the spring wouldn't return it. After I got home, I found that the sheave had caught on the handle on the inside and causing the handle to not work properly. So I had to loosen the adjustable pulley for enough slack to get the sheave free at the same time keeping tension on the wire so it wouldn't unspool. Then re-tighten the pulley and re-adjust the window for right and left height as there was now more cable between the spool and right side clamp block, thus the right side of the window sagged. At least I was able to go all of this without having the wire get loose on the spool.

After I had written this up, I received an email from Ron Sparling. He said that a Ferrari mechanic had told him that new motors come with a retainer clip holding the wire on the spool. When he was working on his car (8709), he made a clip out of steel.The next time I have to fool with these spools, I'll definitely make a clip. Thanks, Ron.