Windshield Wipers

The knurled fitting that is on the end of the shaft was loose on the passenger side. I had tried to peen it in place a couple of times, but it would just loosen again in a couple of days. So I decided to pin it in place with a tiny roll pin. What I didn't realize was that the body of the wiper wheel box sticks up inside of the fitting. So my pin was partially through the box. It would move up about 1/2 way and then stick.

Of course I ignored the problem as I didn't need the wipers. However, I did hose off the dust on the windshield before our test drive and then forgetfully turned on the wipers to wipe the windshield dry. Up go the wipers and they get stuck. I just turned off the switch, forgetting that they have to go to the end before returning to park. A few miles up the freeway, there's a burning insulation smell. Off (on the same exit!) we go. The motor is so hot that I burned myself getting the fuse box cover open to pull the fuse. Then some more burns disconnecting the wiring to the motor so I could replace the fuse and have everything else on that circuit work.

Notice the closeness to the fuse box

So I start to remove the wiper motor. For those who don't know, the Ferrari (and other Italian cars) use a pretty unique and space saving way of actuating the wiper arms. Coming out of the wiper motor is a spring wire widely wound around a center core. The motor moves the spring wire and core back and forth inside a series of fixed tubes. At the first wiper arm pivot (passenger side), there's a wiper wheel box.

Wiper Wheel Box

As you can see, the coiled wire acts like a screw that rotates the gear on the shaft as the wire is pushed back and forth by the motor thus rotating the arm around and back.

Now the pin through the knurled fitting (see arrow) was hitting against the housing about 1/2 way through the cycle. In order to remove the wiper motor, you have to completely pull out the spring wire out of the body. Of course, pulling the wire would rotate it the other direction until it stuck again. I didn't put two and two together until several hours later after disassembling part of the dash to look at the wiper box. Eventually I decided that the roll pin could be part of the problem so I drove it out to eliminate it. Then the wire pulled right out with the shafts turning round and round just like they're supposed to.

After determining that the motor was truly fried, I found a local semi-retired person that fixes wiper motors. He's got several large boxes with old Lucas wiper motors. So a week later I had mine back with a used armature.

I still had the problem of the knurled fitting coming loose. I removed the wiper wheel box (as I already had removed the glove box for access). Then I was able to clearly see how I had caused the problem. This time I drilled the hole for the pin using the drill press where I could line it up exactly where it needed to be.

A note from another 330 GT owner:

What do you do when the serrated drive for the wiper arm is worn beyond

redemption, and there is nothing available from the usual Ferrari parts

suppliers?

Well, buy a Mini wiper wheel box for £10, strip the serrated drive part from the

Mini part, and fit it to the Ferrari spindle. Works perfectly!

A complete cleaning of the wire and new grease as I re-assembled it put everything back right.

One thing that I did notice was that each wiper wheel box moved easier for about half of the revolution and much harder in the other half. I assume that the easy half is where for normal wiper action was and it had just worn into a smoother action. In order to get the actions back into the easy half, I marked each shaft and fitting where the beginning of the easy part was. Then I assembled the wire and motor noting where the lines on the fitting ended up. Then after removing the wire again and by adjusting each wiper wheel box for the difference I was able to install the wire and motor so that each wiper arm was working in the easy half of the rotation. I don't know if I really needed to do this, but the wipers do work quite nicely now.

A while ago, I noticed that the motor only worked on the low speed. This is with the switch in either position. I had bought a used wiper motor assembly, but never got around to testing nor installing it. Then a new one came up on eBay and Lowell Brown's car had the same problem. So I decided I should figure out if the used one would work, and if not, make sure that Lowell and I weren't bidding against each other. A quick electrical test showed that it wasn't working and further, when I took the end cap off, it had been cannibalized with the armature and brush assembly missing. No wonder it didn't work. The picture on the right is what it should look like.

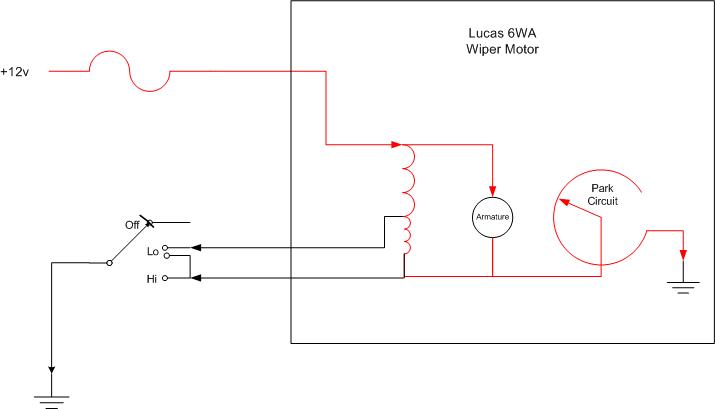

Lowell and I had talked about how the 2 speed operation would work. He mentioned that the usual way was to have a second field coil that was energized for the higher speed. I spent some time doing an electrical diagram, so now I know more than I ever wanted to know about Lucas 2 speed 6WA wipers. Here is the circuit with the wipers off and parked.

As you can see, the field windings are in series with both being used in high

speed. The park circuit is pretty simple. A partial circular ring

(in the transmission) is electrically connected to the field windings and

armature. A

contact grounds that ring so the motor continues to work until the contact hits

the missing portion of the ring which cuts the power and the motor stops with

the wiper blades parked. You can adjust where the wipers park by rotating

the round assembly that had the ring in it. However, I have found that

it's easier just to remove the wiper arms and set them where you want once the

motor is in the park position. Notice that the motor will try to park the

blades even if they are jammed and the switch is off. This will burn up

the armature as described above. The schematic shows the circuit while

parking is occurring.

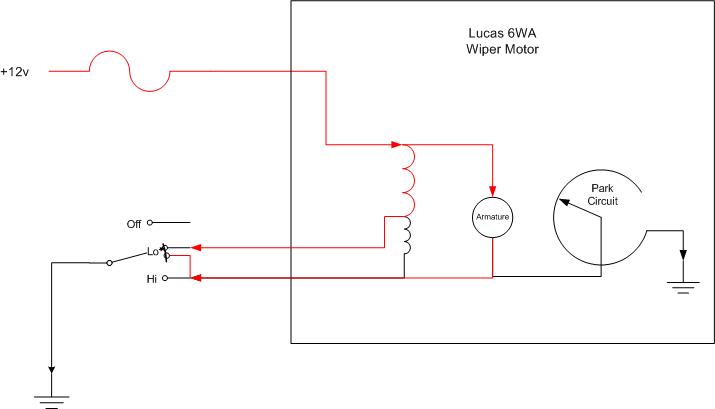

In low speed, the current goes through one winding and the armature to ground at the switch. In low speed, both wires are grounded, thus causing the second field winding to not be energized.

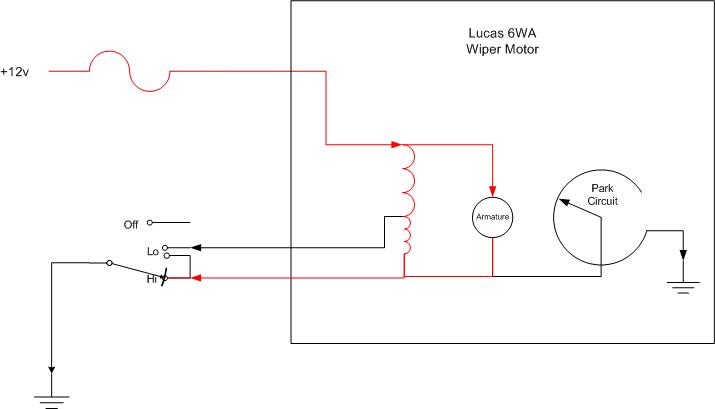

In high speed, the current goes through both windings and the armature to ground at the switch.

At this point, I can't understand how grounding either lead could make the wiper work in low speed, unless the field windings are internally shorted. So the next step is to take the wiper assembly out of the 330 and do some more testing on it. Hopefully the field windings will be bad in it and have good ones in the used motor that I can use.

I spent a lot of time swapping parts and playing with my wiper motor. During that I found out a couple of things. One, the stator is mounted in the case and then machined so the armature will fit. So you can't just swap stators as the armature will not rotate freely. Second, I had misunderstood how the motor works. Instead of either one or the other wires being grounded for low and high, both are grounded on low and only one is on high. With that knowledge, my wiper motor worked properly on the bench and the wiper switch does ground the wires properly. So now I have to check it out in the car and reinstall it.

Here's a video of the how the transmission converts the rotary action of the motor into the linear action of the spring wire.

Got everything back together and into the car. Works fine, perhaps I just had a loose wire (the low speed one would make it work on high on both settings). Anyway, I learned quite a bit about how the wiper system works electrically.

There was a NOS wiper motor on eBay, so I went ahead and bought it. The body of the motor is painted with a gray hammered paint, while the rest is just natural aluminum or zinc plated.